Shahidul Islam, Mohd Azrin Mohd Said, Rubiyah Baini, Shirley Johnathan Tanjong

Faculty of Engineering

Universiti Malaysia Sarawak

Kota Samarahan, Sarawak, Malaysia

Abstract

This research project focuses on building a pilot plant with anaerobic reactor (AR) and Nano membrane filtration (NMF), and to investigate the performance of the pilot plant in producing biogas and water from the palm oil mill effluent (POME). The broad objective of the work is to model an economically and environmentally sustainable solution for POME treatment, in line with three sustainable development goals: SDG-6 (clean water), SDG-7 (clean energy), and SDG-13 (climate actions). The proposed pilot plant is designed based on findings of several laboratory-scale experiments, using a batch anaerobic reactor (BAR) with C/N enriched inoculum for digesting the total organic material (TOM) of POME and using Nano membranes for separating TOM from effluent of BAR. The BAR will be operated at temperature 350C with various range of manipulating variables for digesting TOM. The Nano membrane will be operated at feed pressure range from 60 to 120 psi for separating TOM from the effluent. The findings of this research would be useful in optimizing the biogas and water production from POME. The novelty of the proposed research is to use a ‘two stage anaerobic reactor and nano membranes in series for optimizing the performance of POME treatment in lign with expected contribution to achieve the UN Agenda 2030.

Keywords: Palm Oil Mill Effluent, Anaerobic Digestion, Waste to Energy [WtE], Production and Productivity, Nano- Membrane; Environmental Sustainability, Climate Change

1.0 Background of Water Resource Recovery from POME

Malaysia currently accounts for 39 percent of world palm oil producer (17.73 million tons) which is about 44 percent of global export market share. The average earning of Sarawak’s palm oil industry is about RM 8.0 billion per year contributing to the state economy especially in the aspect of employment generation and economic growth. The challenges faced by palm oil industry are potential carbon emission and pollution from solid biomass and POME, which possibly contributes to climate change (Shahidul et al. 2019; Eugene et al. 2019). Currently, palm oil mills have been using several types of anaerobic digester, and it was reported that the biogas and quality effluent production performance was appeared to be poor and not technically and financially feasible to be used (Ahmed et al. 2015; Chan and Chong 2019; Shahidul et al. 2018). It has been widely claimed that due to the poor performance of anaerobic digesters, the palm oil mills are reluctant to install anaerobic technology (Ahmed et al. 2015; Chan and Chong 2019); thereby the mills continue using the traditional POME treatment method (Jefferson, Kanakaraju, and Tay 2016). It has also been found that there is a research gap exists in POME treatment in reducing TOM. Indeed, this research is done to reduce the research gap in improving the performance of anaerbic reactor, and also to produce water and biogas from POME in lign with expected contribution to achieve SDG-6(Clean water for all), SDG-7(clean energy) and SDG-13( climate actions) towards achieving the UN Agenda 2030 (United Nations 2015).

1.1 Current State of the Art of POME Treatment

Biodegradation of POME produces methane (CH4), carbon dioxide (CO2) and hydrogen sulphate (H2S) that are emitted to the air as greenhouse gas (GHG). In order to minimize GHG emission, several types of AR have been used to digest TOM. It has been reported that the C/N, pH, HRT, SRT, temperature and OLR of substrate inside the AR plays a vital role in decomposing TOM for producing biogas (Ahmed et al. 2015; Chan and Chong 2019; Iskandar et al. 2018).

1.1.1 Performance of Anaerobic Reactor in POME treatment

Eugene et al. (2019) and Abdelgadir et al. (2014) have conducted studies to reveal the effect of pH (from 6.9 to 7.5) on TOM reduction from POME. The findings demonstrated that performance of anaerobic reactor has a positive effect on anaerobic digestion process .The published reports have also demonstrated that the anerobic digestion of POME leads to acidic and toxic environment in the anerobic reactor with pH less than 6.6, which negatively associated with digestion process and biogas production ((Abdelgadir et al. 2014; Eugene et al.2019).

Siddique et al. (2016) and Poh and Chong (2009) revealed that at higher HRT (4<HRT<8) in anaerobic process, the contact time between microbial communities and organic substance increase which contributed to the increasing of digestion performance of substrate and result in the increasing of biogas production and quality effluent from POME ( Seman at el. 2019; Shahidul et al.2018; Siddique et al. 2016).

Eugene et al. (2019) and Abdelgadir et al. (2014) stated that SRT has a positive and significant (p-value<0.05) effect on TOM digestion, and it is effective between SRT 13 days to 20 days. It was also reported that beyond that time limit, the TOM utilization rate in digestion process would reduce; Abdelgadir et al. (2014), Halalsheh et al. (2005), Shahidul, Malcolm, et al. (2018), Krishnan et al.(2017), Mao at el.(2015) and Nayono (2010) revealed that in POME treatment process, the OLR is positively associated with anaerobic digestion process and has a significant effect (p-value<0.05) on biogas production from TOM. It was stated that at OLR higher than 5.0 g.m-3. d-1, the biogas production tends to reduce; and at much lower than (≤ 3.5 g.m-3. d-1), the digestion perfromance also tends to reduce (Fang et al. 2011; Krishnan et al. 2017; Malakahmad and Yee 2014; Mao et al. 2015; Nayono 2010).

It was stated that the carbon to nitrogen ratio (C/N) between 26 and 32 is required to provide optimum level of carbon and nitrogen for anaerobic bacteria growth in the digestion process (Nurliyana et al. 2015). At lower C/N (C/N<26), the nitrogen concentration in the digestion process get higher contributing to acidic environment. At the higher C/N (C/N>35), the nitrogen concentration in the digestion process suffer lack of nitrogen and tends to reduce the activities of the bacteria. In both cases, the anerobic proecss exhibits a poor perfromance in TOM digestion (Esposito et al. 2012; Eugene, J. J, Shahidul, M. I., & Mamunur 2019; Nurliyana et al. 2015; Zakarya et al. 2016).

Membrane technology (NMF) has been given priority by scientists and engineers in recent years as a tool for separating dissolved solids from bio-fluid. The NMF has been successfully used in water prodcution from wastewater as well (Fakhru’l-Razi 1994; Liew Abdullah et al. 2005). However, Abdurahman et al. (2011) and Espinoza-Gómez (2003) revealed that membrane technologies specially NMF is a potential separation means for reducing dissolved solid from bio-fluid like POME (Heriberto et al. 2004; Abdurahman et al. 2011).

The literature review concludes that the performance of anerobic digester depends on pH, HRT, SRT, C/N and OLR. All these manupulating variables have both negative and positive effect on the performance of anerobic digestion process in converting TOM to biogas and to produce dischargeable effluent from POME.

2.0 Problems in POME Treatment and Research Objective

The global production volume shown that the CPO potential is about 74.0 million metric tons in a year (Shahbandeh 2020). Malaysia shares about 40% of global CPO. Indeed, the CPO processing is an identified GHG emission source and a primary driver of climate change. In Malaysian perspective, the carbon (CO2eq) emission potential of POME is approximately 28m3 per ton of POME . It was reported that carbon (CO2eq) contains about Methane (CH4 ≥65%) which is source of biogas based energy. The estimated energy potential of POME in Malaysia is about 13,600 MWh per Year (Shahidul and Malcolm, 2018).

However, a few palm oil mills have been using anaerobic digester for converting POME into biogas and dischargeable effluent, but the success records are not satisfactory. It is also reported that a few mills are discharging poor quality effluent to the environment due to lack of required technology. However, it was found that palm mills are struggling to comply with the environmental regulations and they need an affordable and efficient technology for POME treatment (Seman et al., 2019; Shahidul and Malcolm, 2018). A few researches have reported that the performance of AR in POME treatment is less than 65% (Eugene, et al, 2019; Ng et al. 2012; Shahidul, et al., 2018). However, the reported problem in palm oil mill domain demonstrated that in many cases, the process used for decomposing TOM is not fully able to meet the requirement of the Department of Environment(Eugene et al., 2019; Ng et al. 2012; Shahidul et al. 2020; Shahidul et al.2018). Indeed, this research is designed to address TOM reduction problem from POME to produce biogas and recyclable water, and the main objective is to build a pilot-scale plant with AR and NMF; the Biogas and fresh water potential from POME will be determined .

3.0 Research Methodology

The research activities will be divided into two parts. In the first part, BAR will be used for the digestion process of TOM to produce biogas and effluent. In the second stage, Nano membranes will be used to separate TOM from the Bar’s effluent. The methodology included are sample (POME) collection, pilot-scale plant setup and experiments according to design experiments from Design Expert (version 2018) software, inputs-outputs data collection of experiments, and data analysis. The Design of Expert (version 2018) software (DOE) will be used to estimate the required experimental runs (Chan and Chong 2019), and to analyse experimental data.

3.1 Experimental Setup

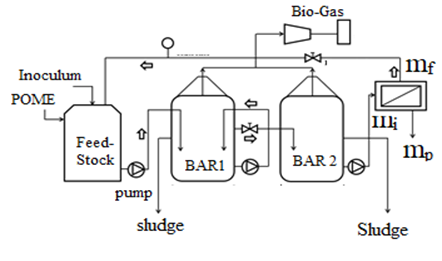

Figure 1 shows the experimental setup that includes major parts such as the feed stock tanks, pumps, BAR and NMF.

|

Figure 1: Machinery of pilot plant with Bar and NMF

3.2 Membrane Setup for Waste Biomass Separation from Effluent

Three NMF will be used, and similar membranes have also been used by several researchers in solid separations process from effluent ( Espinoza et al., 2001; Heriberto at al., 2003; Heriberto at al., 2004). The properties of NMF are listed in Table 1.

Table 1: Properties of Nano Membrane Used

|

Membrane Type |

Surface Areas |

Pore Diameter (nm) |

Membrane CODE |

Hydraulic Permeability (10-14 m) |

|

NF270-4040 |

7.6 m2 |

≈0.8 |

NMF1 |

0.899 |

|

NF90 4040 |

7.6 m2 |

0.68 |

NMF2 |

0.929 |

|

GE NF4040 |

6.5 m2 |

0.10 |

NMF3 |

0.699 |

3.3 Research Variables

The independent research variables are HRT, SRT C/N, pH and OLR. The range of independent variables and experimental runs will be estimated by using DOE (Chan and Chong 2019).

3.4 Method of Conducting Experiments

Feedstock will be prepared with C/N enriched inoculum. The pH in the substrate will be adjusted by adding sodium hydroxide (NaOH) (Choi et al. 2013; Eugene, et al. 2019). The BAR1 will be used for hydrolysis and acidogenesis and it will be operated at pH 5.0 and temperature of 35℃ for 2 days [HRT 2 days] in order to break down the long chain organic materials into short chains (Eugene et al., 2019;Mamimin et al. (2015; Kim et al. (2015). In BAR2, the acetogenesis and the methanogenesis processes will be performed at pH from 6.5–7.5 and temperature of 35℃. The HRT, SRT and OLR will be varied based on the DOE estimate (Fang et al. 2011; Halalsheh et al. 2005; Mahmoud et al. 2004; Malakahmad and Yee 2014).

Effluent of BAR will be fed to NMF for clean water production. The feed pressure and cross flow velocity of effluent will be determined from the NMF’s manufacturers operations manual. The outputs of NMF such as the volume and dissolved solids of concentrates and permeate, will be determined as per the method suggested by Van and Olieman (1991).

The concentrated parts of effluent (mf) enriched with TOM will be recycled through BAR1, BAR2 and NMF. The data of TOM, biogas and water will be collected from BAR and NMF, and will be analysed to achieve research objectives.

4.0 Expected Research Outcomes, Benefits and Implications

The estimated outputs from the pilot plant are 0.30m3 biogas per m3 of POME and 0.6m3 water per m3 of POME. The outcomes of the proposed research have some practical benefits to the society in achieving economic and environmental sustainability. The project will contribute to develop human capital with required knowledge to address the challenges with POME treatment related to carbon emission and air pollution which are contributing to climate change.

4.1 Implications of Research Outcomes

The findings of this research are expected to have a few implications in economy, health and environment aspects in Sarawak. The technologies and methods proposed in this research would be a guideline in recovering waste biomass and organic material from POME for reducing carbon emission (CO2eq). Additionally, the method described in this paper would be useful to increase the quality of dischargeable effluent which would contribute to reduce the pollution in the air, water and soil. These findings would be a useful reference for engineers and researchers working with palm oil mills to provide quality service in achieving higher efficiency in producing biogas and quality effluent from POME.

5.0 Research outcomes and Conclusion

The pilot plant will be developed and operated based on the outcomes of several laboratory scale researches conducted since 2013. The expected outcomes from the pilot plant would contribute to establish a solid path to recover clean water resources from hazardous POME. The outcomes would also be a guidline for engineers and industries to design the process for producing quality effluent from POME. The proposed pilot plant would be a model to produce commercial scale POME treatment plants that is expected to contribute in the achievement of economic and environmental sustainability in the state of Sarawak.

6.0 References

Abdelgadir, Awad et al. 2014. “Characteristics, Process Parameters, and Inner Components of Anaerobic Bioreactors.” BioMed research international 2014: 841573.

Ahmed, Yunus, Zahira Yaakob, Parul Akhtar, and Kamaruzzaman Sopian. 2015. “Production of Biogas and Performance Evaluation of Existing Treatment Processes in Palm Oil Mill Effluent (POME).” Renewable and Sustainable Energy Reviews 42.

Chan, Yi Jing, and Mei Fong Chong. 2019. “Palm Oil Mill Effluent (POME) Treatment—Current Technologies, Biogas Capture and Challenges.” In Green Technologies for the Oil Palm Industry, Springer, Singapore, 71–92.

Choi, Won-Ho et al. 2013. “Anaerobic Treatment of Palm Oil Mill Effluent Using Combined High-Rate Anaerobic Reactors.” Bioresource technology 141: 138–44.

Espinoza-Gómez, H., and S. W. Lin. 2001. “Development of Ultrafiltration Membranes from Acrylonitrile Co-Polymers.” Polymer Bulletin 47(3–4): 297–304.

Espinoza-Gómez, Heriberto, and Shui Wai Lin. 2003. “Development of Hydrophilic Ultrafiltration Membrane from Polysulfone-Polyvinylpyrrolidone.” Revista de la Sociedad Química de México 47(1): 53–57.

Espinoza-Gómez, Heriberto, Shui Wai Lin, and Eduardo Rogel-Hernández. 2004. “Nanofiltration Membrane Pore Diameter Determination.” Journal of the Mexican Chemical Society 48(1): 15–20.

Esposito, G. et al. 2012. “Anaerobic Co-Digestion of Organic Wastes.” Reviews in Environmental Science and Biotechnology 11(4): 325–41.

Eugene JJ, Shahidul MI, and Mamunur R. 2019. “Optimizing Organic Materials Reduction from Hazardous Industrial Bio-Effluent by the Aid of C/N Enriched Inoculum: An Approach to Use Traditional Anaerobic Reactor to Achieve Environmental Sustainability.” Sci.Int.(Lahore) 31(4): 649–54.

Fakhru’l-Razi, A. 1994. “Ultrafiltration Membrane Separation for Anaerobic Wastewater Treatment.” In Water Science and Technology, , 321–27.

Fang, Cheng, Sompong O-Thong, Kanokwan Boe, and Irini Angelidaki. 2011. “Comparison of UASB and EGSB Reactors Performance, for Treatment of Raw and Deoiled Palm Oil Mill Effluent (POME).” Journal of Hazardous Materials 189(1): 229–34.

Halalsheh, M et al. 2005. “Effect of SRT and Temperature on Biological Conversions and the Related Scum-Forming Potential.” Water Research 39(12): 2475–82.

Irvan, I, Bambang Trisakti, Vivian Wongistani, and Yoshimasa Tomiuchi. 2012. “Methane Emission from Digestion of Palm Oil Mill Effluent (POME) in a Thermophilic Anaerobic Reactor.” International Journal of Science and Engineering.

Iskandar, Muhammad Johan, Azizah Baharum, Farah Hannan Anuar, and Rizafizah Othaman. 2018. “Palm Oil Industry in South East Asia and the Effluent Treatment Technology—A Review.” Environmental Technology and Innovation 9.

Jefferson, Emra Elinda, Devagi Kanakaraju, and Meng Guan Tay. 2016. “Removal Efficiency of Ammoniacal Nitrogen from Palm Oil Mill Effluent (Pome) by Varying Soil Properties.” Journal of Environmental Science and Technology 9(1): 111–20.

Khemkhao, Maneerat, Somkiet Techkarnjanaruk, and Chantaraporn Phalakornkule. 2015. “Simultaneous Treatment of Raw Palm Oil Mill Effluent and Biodegradation of Palm Fiber in a High-Rate CSTR.” Bioresource Technology 177: 17–27.

Krishnan, Santhana et al. 2017. “Role of Organic Loading Rate in Bioenergy Generation from Palm Oil Mill Effluent in a Two-Stage up-Flow Anaerobic Sludge Blanket Continuous-Stirred Tank Reactor.” Journal of Cleaner Production 142: 3044–49.

Liew Abdullah, A. Ghaniey et al. 2005. “A Kinetic Study of a Membrane Anaerobic Reactor (MAR) for Treatment of Sewage Sludge.” Desalination 183(1–3): 439–45.

- Shahbandeh. 2020. Production Volume of Palm Kernel Oil Worldwide from 2012/13 to 2019/20. https://www.statista.com/statistics/613479/palm-kernel-oil-production-volume-worldwide/.

Mahmoud, Nidal, Grietje Zeeman, Huub Gijzen, and Gatze Lettinga. 2004. “Anaerobic Stabilisation and Conversion of Biopolymers in Primary Sludge - Effect of Temperature and Sludge Retention Time.” Water Research 38(4): 983–91.

Malakahmad, Amirhossein, and Witton Yee. 2014. “Production of Energy from Palm Oil Mill Effluent during Start-up of Carrier Anaerobic Baffled Reactor (CABR) Equipped with Polymeric Media.” Nihon Enerugi Gakkaishi/Journal of the Japan Institute of Energy 93(5): 505–10.

Mao, Chunlan, Yongzhong Feng, Xiaojiao Wang, and Guangxin Ren. 2015. “Review on Research Achievements of Biogas from Anaerobic Digestion.” Renewable and Sustainable Energy Reviews 45: 540–55.

N.H. Abdurahman, Y.M. Rosli, N.H. Azhari, S.F.Tam. 2011. “Biomethanation of Palm Oil Mill Effluent (POME) by Membrane Anaerobic System (MAS) Using POME as a Substrate.” World Academy of Science, Engineering and Technology 51(419–424).

Nayono, Satoto Endar. 2010. Anaerobic Digestion of Organic Solid Waste for Energy Production. Technische Informationsbibliothek u. Universitätsbibliothek.

Ng, Wendy Pei Qin et al. 2012. “Waste-to-Wealth: Green Potential from Palm Biomass in Malaysia.” Journal of Cleaner Production 34: 57–65.

Nurliyana, M. Y. et al. 2015. “Effect of C/N Ratio in Methane Productivity and Biodegradability during Facultative Co-Digestion of Palm Oil Mill Effluent and Empty Fruit Bunch.” Industrial Crops and Products 76: 409–15.

van Riel, Jan, and Cees Olieman. 1991. “Selectivity Control in the Anion-Exchange Chromatographic Determination of Saccharides in Dairy Products Using Pulsed Amperometric Detection.” Carbohydrate Research 215(1): 39–46.

S.Z.A. Seman, I. Idris, A. Abdullah, I.K. Samsudin, M.R. Othman. 2019. “Optimizing Purity and Recovery of Biogas Methane Enrichment Process in a Closed Landfill.” Renew. Energy 131: 1117–27.

Shahidul, M. I., Rubiyah Baini, et al. 2018. “Effects of Hydraulic Retention Time and Solid Retention Time of POME on COD Removal Efficiency.” International Journal of Automotive and Mechanical Engineering 15(2): 5347–55.

Shahidul, M. I., M. L. Malcolm, J. J. Eugene, and R. Mamunur. 2018. “Optimization of Factors Affecting Biogas Production from POME.” Science International (Lahore) 30(6): 851–59.

Shahidul, M.I. 2020. “Engineering Education for Achieving Sustainable Development Goals by 2030: Revealing the Paths for Challenging Climate Change and COVID-19.” Sci. Int. (Lahore) 32(4): 403–10.

———. 2020. “The Role of Engineering in Mitigating Global Climate Change Effects: Review of the Aspects of Carbon Emissions from Fossil Fuel-Based Power Plants and Manufacturing Industries.” In Encyclopedia of Renewable and Sustainable Materials, , 750–62.

Shahidul, M.I., M.L. Malcolm, J.J. Eugene, and M.I. Sharafatul. 2019. “A Novel Study On Biogas Production From Palm Oil Mill Effluent With Two-Stage Anaerobic Digester And Nano Membrane.” Science International (Lahore) 31(6): 811–19.

Shahidul, M.I., Ching Hung Ting, Man Djun Lee, and Begum Shahnur. 2015. “Seawater Desalination for Environment and Economic Sustainability: A Case Study at Sadong Jaya Pilot Plant.” International Journal of Engineering Research and Management (IJERM) 2(8): 69–74.

Shahidul, M I, M L Malcolm, and J J Eugene. 2018. “Methane Production Potential of POME: A Review on Waste-to-Energy [WtE] Model.” Sci Int (lahore) 30(5): 717–28.

Siddique, Md Nurul Islam, Mimi Sakinah Abdul Munaim, and Zularisam Ab. Wahid. 2016. “Role of Hydraulic Retention Time in Enhancing Bioenergy Generation from Petrochemical Wastewater.” Journal of Cleaner Production 133: 504–10.

United Nations. 2015. “Transforming Our World: The 2030 Agenda for Sustainable Development.”

Zakarya, Irnis Azura, Nurul Kassim, Tengku Nuraiti Tengku Izhar, and Siti Noor Baya Khalib. 2016. “Effect Of PH, Alkalinity And C: N Ratio During Anaerobic Digestion Of Palm Oil Mill Effluent In Two-Phase Reactor With Food Waste As A Feedstock.” Journal Multidisciplinary Engineering Science and Technology 3: 6127–31.